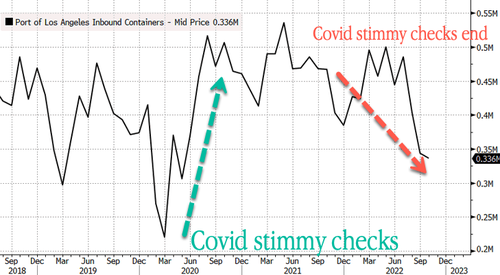

About a year ago, long dragons were lined up outside the west coast of the west coast of the United States. Those container ships that cannot be leaning have to wait for several days or even weeks on the sea. However, today, the peak shipping season before the most busy shopping season of the year has completely showed another scene.

According to the latest data released this week, Los Angeles and Changtan Port adjacent to the West Coast processed 630,231 inbound containers in October, a 26%decrease from the same period last year. Freight throughput.

Geney Seroka, executive director of Los Angeles Port, said on Tuesday that the Los Angeles Port has gone through the quietest October since 2009.

Seroka pointed out that freight throughput has declined since August. The biggest factor behind the landslide caused by throughput is "due to the long -lasting labor negotiations, importers are transferring more goods to the ports on the east coast and the Gulf of Mexico."

Some shipping industry officials have hoped that the labor and management negotiations starting in May this year will not be delayed for a long time. However, the negotiation has been stagnant for a few months so far, and officials now believe that it will not end in early 2023. The negotiations involved more than 22,000 workers from 29 ports from Washington to California, and about 70 employers operating cargo loading and unloading business.

Los Angeles Port and Changtan Port are often regarded as the busiest ports in the United States. These two ports have usually processed about 40%of the container in the United States. They are also the main port portals of Chinese goods entering the United States.

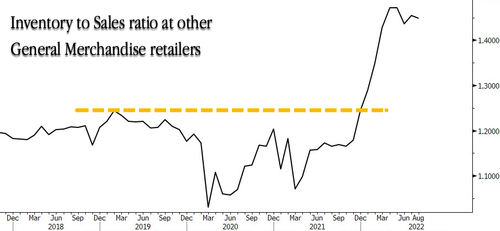

In addition to labor disputes, the freight volume of ports before the arrival of the shopping season at the end of the American traditional year has fallen sharply, and it is reminiscent of deeper hidden concerns: whether this indicates that retailers and manufacturers have slowed or stopped from obsession. Overseas ordering is either excessive inventory or demand collapse.

In fact, even if it is a port outside Los Angeles and the port outside of Los Angeles, the overall imported freight volume is declining.

The trade intelligence department of the supply chain software provider Cartesian Logistics System Group stated in its latest report that the overall US container imports in October decreased by 13%compared with the same period last year.

Seroka obviously did not deny this. He said that the decline in freight volume decreased due to consumers' expenditures for family supplies such as furniture and electrical appliances.

"We predict in May that excess inventory is the reverse bull whip effect, which will cool down the prosperous freight market. Now it is the peak shipping season, but the freight company has reduced capacity Overseas orders were canceled, "Seroka said.

The well -known financial blog website Zerohedge also pointed out that the inventory of major companies is bloated. This can be seen from the library sales ratio that the ratio has reached the highest point of decades -forcing importers to reduce shipments from overseas suppliers.

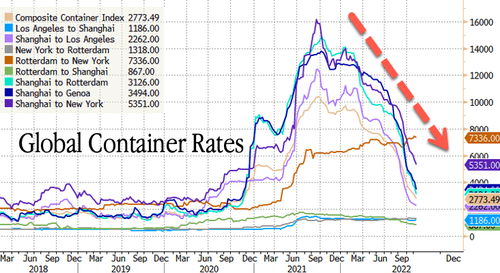

Because importers were trapped by inventory, they reduced orders, which led to the plunge in the freight of containers, and even some large shipping companies have canceled some routes.

As we reported before, with the decline in global trade volume, another problem began to appear: the empty containers in the port have to be released. Traders and consignors have pointed out that this is not a sign of the global economy being returning to normal, but a sign of decline in consumer demand.

Previous:The shipping price of the United States West has dropped more than 20%in 30 days, to $ 1632/Feu!

Next:The country's largest trailer company requires all employees to stop working indefinitely, and 17 po